Restoring Your Vehicle’s Engine to Peak Performance

Is your engine underperforming? An engine overhaul and rebuilding service can restore its peak performance. This article explains what engine rebuilding involves, signs you need it, and its benefits.

Key Takeaways

- Signs that your vehicle may need an engine rebuild include loss of power, excessive oil consumption, exhaust smoke, strange engine noises, and persistent check engine light.

- Engine diagnostics can help identify the need for an engine rebuild.

- Choosing to rebuild an engine instead of replacing it can be cost-effective, extend the vehicle’s life, improve efficiency, and reduce environmental impact by reusing parts.

Understanding Engine Rebuilding

Engine rebuilding, a crucial aspect of engine repair, is both an art and a science. It involves:

- Disassembling the engine

- Cleaning it thoroughly

- Inspecting every part for wear and tear, including the engine block

- Replacing or repairing components as needed to restore it to full functionality

This process demands a high level of skill, precision, and experience because even the smallest misalignment can lead to significant engine problems down the road. The labor-intensive nature of engine rebuilding means it can take weeks or even months, particularly for those who lack experience.

The process of rebuilding an engine includes the following steps:

- Thoroughly clean the engine to remove dirt and grease that can affect efficiency and performance.

- Inspect each part to determine if it needs to be repaired or replaced.

- Repair or replace any damaged or worn parts.

- Reassemble the engine using the repaired or replaced parts.

- Test the rebuilt engine to ensure it operates at its best.

This process ensures that the engine is in optimal condition and ready for use at the repair facility.

The rebuilding process requires exact precision. Every part must be aligned and within specifications to guarantee optimal performance and longevity. This level of detail ensures that the engine not only runs smoothly but also maintains its performance over time. By the end of the rebuilding process, the engine is essentially restored to its original state, ready to deliver the power and reliability you expect from your vehicle.

Signs Your Vehicle Needs an Engine Rebuild: Check Engine Light

Being aware of the early indicators of a deteriorating engine can prevent sudden breakdowns and expensive repairs. One of the most telling signs is a noticeable loss of power and acceleration, indicating that the engine is struggling to perform. Excessive oil consumption is another red flag; it often points to worn-out piston rings or valve seals that can’t keep oil from seeping into the combustion chamber. This issue not only affects performance but also leads to frequent and costly oil top-ups.

Smoke from the exhaust is a clear sign of internal engine trouble. Different colors of smoke can indicate various problems: blue smoke suggests burning oil, black smoke indicates excessive fuel burning, and white smoke can mean coolant is leaking into the engine. Alongside smoke, knocking or pinging noises signal malfunctioning internal components, which could lead to more severe damage if not addressed promptly.

A compression test is a diagnostic tool used to identify engine issues by measuring the pressure in each cylinder, helping to pinpoint problems like worn piston rings or leaking valves.

Some serious symptoms of engine problems include:

- Difficulty starting the engine

- Engine misfires or car stalling

- Loss of power or acceleration

- Strange noises coming from the engine

- Overheating, often caused by a failing cooling system

- A persistent check engine light, indicating various issues

- High mileage and the age of your vehicle, which may necessitate an engine rebuild to address wear and tear.

Benefits of Engine Rebuilding Over Replacement

Choosing to rebuild an engine over replacing it entirely offers numerous benefits. Firstly, it is often more cost-effective. Purchasing a brand-new engine can be prohibitively expensive, whereas rebuilding your existing engine can save you a significant amount of money. Additionally, an engine rebuild can extend the life of your vehicle by restoring the engine to its original specifications, ensuring that it runs smoothly and efficiently for many more miles. Compared to a remanufactured engine, rebuilding allows for more customization and attention to specific issues your engine may have.

Rebuilding an engine offers several benefits, including:

- Targeted improvements: Specific issues and worn-out components are addressed directly, leading to better overall performance.

- Improved efficiency and power: A rebuilt engine often operates more efficiently and with improved power compared to its pre-rebuild condition.

- Environmental friendliness: Engine rebuilding involves reusing and refurbishing existing parts, reducing waste and the need for new materials.

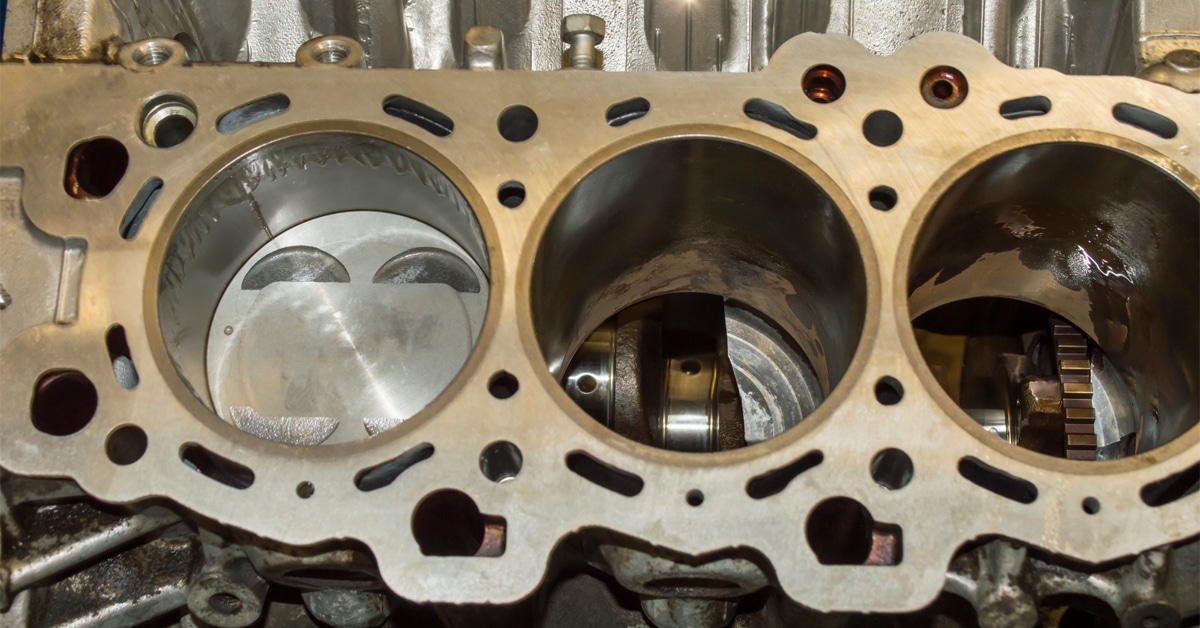

Key Components in an Engine Rebuild

Several vital components are involved in an engine rebuild, each contributing significantly to the engine’s overall functionality. The pistons, for instance, compress the air-fuel mixture and transfer the force generated from combustion to the crankshaft. Piston rings, which seal the combustion chamber, prevent the air-fuel mixture from leaking into the crankcase, ensuring efficient combustion and power delivery.

Some vital components of automotive engines include:

- Pistons, which move up and down in the cylinders to create combustion

- Connecting rods, which convert the reciprocating motion of the pistons into rotational motion

- Crankshaft, which transfers the rotational motion to turn the wheels

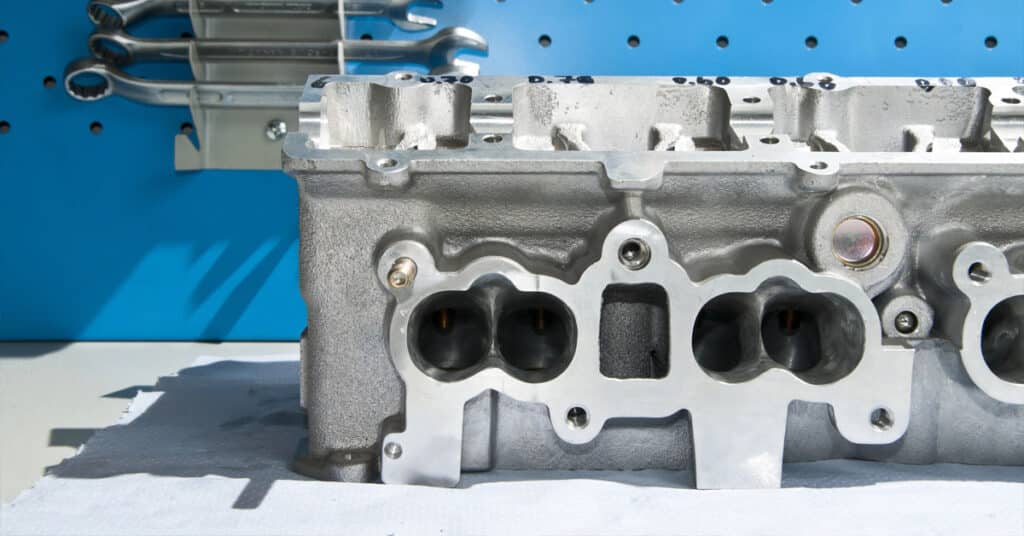

- Cylinder heads, which contain the combustion chambers, valves, and ports to optimize airflow and combustion

- Carburetor (in classic cars) or turbocharger (in turbocharged engines), which are often rebuilt or replaced to ensure proper functioning

These components work together to ensure the engine runs smoothly and efficiently.

Other crucial parts include the water pump, oil pump, and various sensors, which are typically hard to access post-rebuild. Replacing these during the rebuild process can prevent future issues and ensure the engine operates smoothly. The fuel delivery system, including the fuel injection pump and injectors in diesel engines, should also be renewed to maintain proper fuel flow and combustion.

The Engine Rebuilding Process

Engine rebuilding is a process involving various meticulous steps aimed at restoring or even improving the engine’s performance. It all begins with removing the engine from the vehicle and giving it a thorough cleaning to avoid complications during disassembly. An important part of the engine that is often addressed during a rebuild is the valve train.

The process typically involves removing the engine block and disassembling it, setting the stage for a detailed inspection and subsequent repairs.

Disassembly and Inspection

The initial step in the process is to disassemble the engine. This involves:

- Removing external components like the radiator, alternator, and air conditioning compressor

- Taking off parts such as the intake manifold, exhaust manifold, valve covers, and oil pan to access the engine block

- Organizing and labeling all removed parts, bolts, and fasteners to ensure accurate reassembly later.

Once disassembled, each component undergoes a thorough inspection. Parts like the harmonic balancer, crankshaft, and cylinder heads are checked for wear, cracks, or other damages. Techniques such as magnafluxing or using dye penetrants are employed to identify cracks in cast iron or aluminum blocks, ensuring no defect goes unnoticed.

Cleaning and Machining

Cleaning and machining form the cornerstone of the engine rebuilding process. Cleaning involves using specialized solutions and equipment to remove accumulated dirt, grime, and sludge from engine parts, which can complicate disassembly and affect performance. This thorough cleaning ensures that the engine components are free from contaminants that could cause further damage during reassembly.

Machining, on the other hand, reconditions the internal surfaces of the engine. This might involve resurfacing the block, boring cylinders, machining the cylinder bore, or regrinding the crankshaft to restore them to their original specifications. By ensuring that all surfaces are level and smooth, machining helps the engine run more efficiently and reduces the risk of future problems.

Reassembly and Testing

The process of engine reassembly includes the following steps:

- Installing new or refurbished parts that meet OEM standards

- Putting the engine back together in the correct order

- Using new gaskets, gasket set, seals, and bearings

- Ensuring that all clearances and tolerances are within specifications

Careful installation during reassembly is crucial for the engine’s longevity and performance.

The process of rebuilding an engine concludes with the following steps:

- Testing the rebuilt engine to check for proper compression, oil pressure, and coolant flow, ensuring it functions correctly before being installed back into the vehicle.

- Monitoring oil pressure and temperature gauges during initial testing to ensure the engine runs smoothly without overheating.

- Identifying any potential issues during this phase before the engine is deemed ready for use.

Cost Factors in Engine Rebuilding

The cost of an engine rebuild is influenced by a variety of factors. The make and model of the vehicle play a significant role, as parts for some vehicles can be more expensive than others. The extent of damage to the engine is another critical factor; more extensive damage requires more parts and labor, driving up costs.

Replacement parts’ cost is also a major consideration. High-quality parts can be pricey, but they ensure the rebuilt engine’s reliability and performance. Labor costs can vary significantly depending on the vehicle and the complexity of the rebuild.

Overall, engine rebuilds can start at around $2,500 and go up from there depending on these variables.

Routine Maintenance Post-Rebuild: Essential Tips

To ensure the longevity and performance of a rebuilt engine, regular maintenance is paramount. Changing the oil regularly is perhaps the most important maintenance task, as it keeps the engine running smoothly and prevents wear. An oil change is critical to remove contaminants and ensure proper lubrication. It is also important to regularly check other fluids in your vehicle, including engine coolant, power steering fluid, brake fluid, and windshield washer fluid. These components are crucial for the proper functioning of your car and should be maintained to ensure optimal performance.

Other routine maintenance tasks include:

- Replacing the car battery as indicated in the owner’s manual

- Changing spark plugs to improve engine performance and prevent costly repairs

- Replacing the air filter when it becomes dirty to ensure the engine receives clean air, which is vital for efficient combustion

Following these engine maintenance tips can help keep your engine running strong for years to come, potentially avoiding the need for engine repairs or seeking professional engine services, including servicing automotive engines.

Finding a Skilled Technician for Engine Rebuilds

To guarantee quality and reliability, it’s imperative to find skilled technicians for an engine rebuild. Look for ASE certification, which is a key qualification indicating a technician’s expertise. Certifications from recognized institutions further validate a technician’s skills and knowledge. Reputable establishments like Auto-Lab boast experienced ASE certified technicians who can handle complex engine rebuilds with precision.

Reading customer reviews on platforms like Google, Yelp, and Facebook can provide valuable insights into the quality of service provided by a technician. Positive reviews highlight the technician’s expertise and customer service, guiding you to make an informed decision. Combining these reviews with the technician’s certifications ensures you receive high-quality service for your engine rebuild.

Summary

In summary, engine rebuilding is a meticulous process that requires skill, precision, and experience. Recognizing the signs that your vehicle needs a rebuild, understanding the benefits over replacement, and knowing the key components and steps involved can help you make an informed decision. The process, though labor-intensive, can restore your vehicle to peak engine performance, extend its life, and be more cost-effective and environmentally friendly.

By following routine maintenance and finding a skilled technician, you can ensure the longevity and efficiency of your rebuilt engine. So, if your vehicle is showing signs of engine trouble, consider an engine rebuild as a viable option to bring it back to life. Trust in the process, and you’ll be rewarded with a vehicle that runs like new.

Frequently Asked Questions

What is the price of a full engine rebuild?

An engine rebuild may cost around $2,500 to $4,000, including parts and labor, which is approximately half of the cost of a full replacement. Keep in mind that this estimate can vary based on the complexity of the engine and specific issues with the vehicle.

What are the main steps involved in an engine rebuild?

The main steps in an engine rebuild include disassembly and inspection, cleaning and machining, and reassembly and testing. Each step involves meticulous work to restore the engine to its original condition or enhance its performance.

How can I tell if my vehicle needs an engine rebuild?

If your vehicle is experiencing loss of power, excessive oil consumption, smoke from the exhaust, knocking noises, overheating, and a persistent check engine light, it may indicate the need for an engine rebuild. High mileage and age are also important factors to consider.

What are the benefits of rebuilding an engine instead of replacing it?

Rebuilding an engine can be more cost-effective, extend your vehicle’s life, improve its performance, and is more environmentally friendly by reusing and refurbishing existing parts.

What should I look for in a technician to rebuild my engine?

Look for an ASE certified technician and check for certifications from recognized institutions. Reading customer reviews on platforms like Google, Yelp, and Facebook can also help you gauge the quality of their service.

Engine Rebuilding Service Near Me

If your vehicle needs engine repair or replacement, come see us at Autocare Pro’s for the best engine service and repairs in Lake Jackson, Tx. We offer a wide range of services from preventative maintenance, like an oil change to major engine repairs so your vehicle will last longer and run like new again!